| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : HD Boiler

Model Number : Boiler Economizer

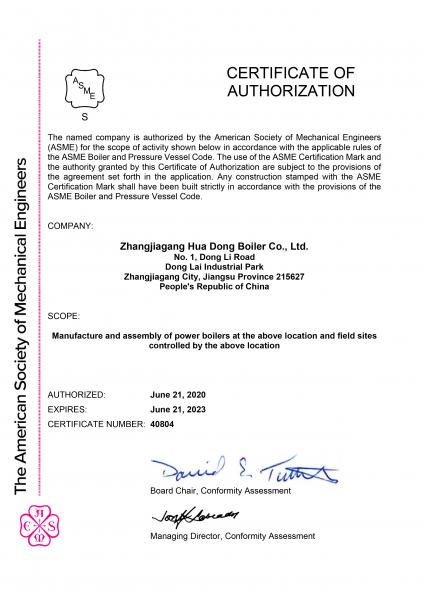

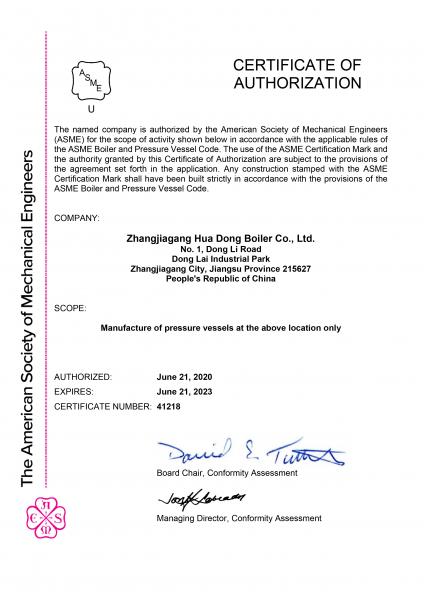

Certification : ASME,EN,ISO,SGS

Place of Origin : CHINA

MOQ : 500 tons

Price : Reasonable

Payment Terms : L/C, T/T, Western Union

Supply Ability : 500 tons/month

Delivery Time : 30 working days

Packaging Details : Seaworthy Packing

Type : economizer

Application : power plant boiler

Color : Customer's Requirement

Fuels : Coal;Oil;Biomass

Standard : ASME&GB

Carbon/Stainless Steel Boiler Economizer For Power Plant Heat Exchanger

Product Information

Economizer is installed on the lower part of the boiler tail flue for recycling the waste heat of smoke, a device of heating boiler feed water into steam drum pressure of saturated water heating surface, because it absorbs the heat of high temperature flue gas, reducing the exhaust temperature of flue gas, save the energy, improve the efficiency, so called economizer tube type economizer pressure without limit, can be used as a boiling type, generally by the outer diameter of 32 ~ 51 mm carbon steel tube in tube with fins and sometimes fin, to improve the effect of heat transfer tube type economizer from horizontal arrangement of parallel bend pipe.

Procedure

Economisers also reduce the potential of thermal shock and strong water temperature fluctuations as the feed water enters the drum or waterwalls. Increasingly stringent environmental regulations limiting nitrogen oxides and sulfur dioxide emission can also affect economizer design. The gas-side heat transfer coefficient is much less than water side heat transfer coefficient. To compensate this, outer surface of the tubes may be finned to increase the surface area of heat transfer. The ultimate goal of economizer design is to achieve the necessary heat transfer at minimum cost. A key design criterion for economizer is maximum allowable flue gas velocity. Higher velocity provide better heat transfer and reduce capital cost.

Specifications

| Name(unit) | Specification(mm) |

| Bare pipe(OD) | 25-1650 |

| Bare pipe(Thickness) | 2-40 |

| Fin (Thickness) | 0.6-3.0 |

| Fin (Height) | 5-30 |

| Fin tube thread pitch | 5-30 |

| Fin tube length | ≤12000 |

Material:Carbon Steel,Alloy,Austenitic Steel(Nickel and Chromium or Manganese)

Quality Control

1. Impact test and Strength calculation report with applied materials information.

2. 100%NDT(non-destructive inspection) report of steel plate, tube and electrode.

3. X-ray, γ-ray and liquid penetrant test inspection report (welding seam): to ensure the quality of the entire boiler.

4. Hydraulic test report: ensure the standard working pressure and safety.

Certificate

|

|

Carbon / Stainless Steel Boiler Economizer For Power Plant Heat Exchanger Images |